No products in the cart.

Products Categories

Our Guarantee

Your Enquiries

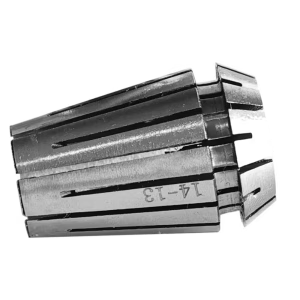

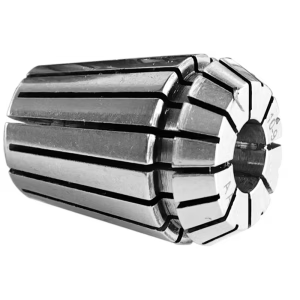

| Short Description | Pictures For Reference |

|---|---|

|

ER collets are a type of tool - holding device commonly used in CNC machines. They are designed to securely hold cutting tools such as end mills, drills, and reamers in the spindle of a CNC machine.

Structure and Working PrincipleThe ER collet system consists of a main shaft or body with a threaded end, a nut, and interchangeable collets. The collets snap into the nut, which is then screwed onto the main body or spindle. The tool is inserted into the collet, and when the nut is tightened, the collet sits in an internal tapered shaft that matches its taper. This taper compresses the collet against the tool, locking it into place. When the collet is loosened, the ring clipped into the collet pulls it away from the taper lock, releasing the collet and the tool. The nut has an eccentric snap ring inside and a taper where the front of the collet sits to compress the top of the collet. The task of the eccentric ring is to clip into the groove of the collet to hold it in place and pull it away from the taper in the body or spindle when loosened.SizesER collets come in various sizes, denoted by numbers after "ER", which represent the approximate opening diameter of the collet in millimeters. For example, an ER16 collet has an opening diameter of about 16 mm. Common sizes include ER8 (for very small tools, 0.5 - 5 mm in diameter), ER - 11 (for tools with diameters between 1 mm and 7 mm), ER - 16 (accommodating tools from 1 mm to 10 mm), ER20 (for tools with diameters between 1 mm and 13 mm), ER25 (fits tools ranging from 1 mm to 16 mm), ER - 32 (can hold tools between 2 mm and 20 mm), ER40 (suitable for larger tools, 3 - 26 mm in diameter), and ER50 (designed for heavy - duty applications, accommodating tools between 10 mm and 34 mm).AdvantagesWide clamping range: They can hold tools of various diameters, reducing the need for multiple collet sizes. High precision: Their design ensures minimal tool TIR, leading to more accurate machining results. The even distribution of clamping force prevents tool slippage, even under high - torque conditions, ensuring consistent results and prolonging tool life.ApplicationsER collets are widely used in various machining operations, including milling, drilling, tapping, grinding, and turning. Their versatility and high - precision gripping make them an essential component in modern manufacturing setups. |

|